Download brochure

More Information About iBWIM

Download brochure

More Information About iBWIM

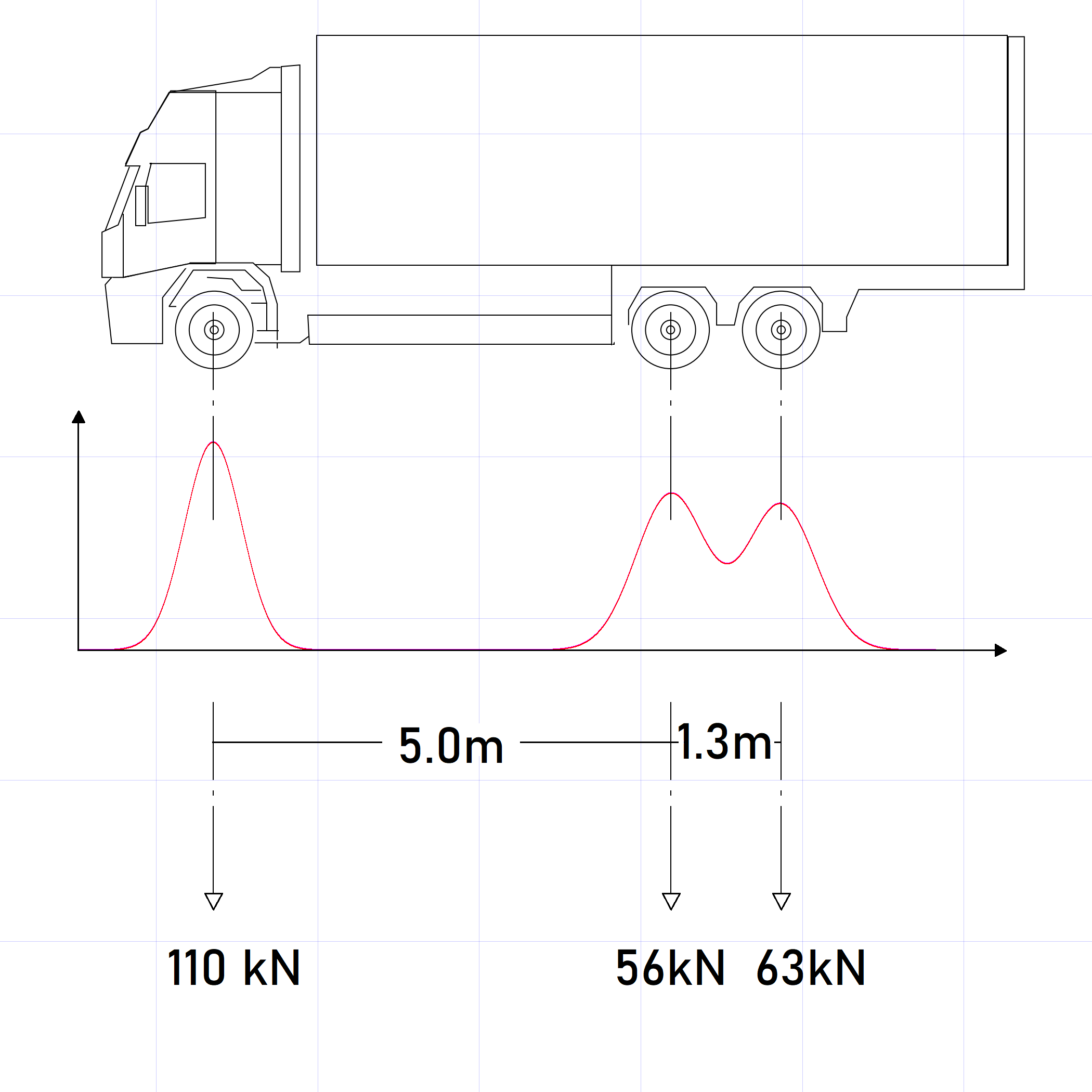

Bridge Weigh in Motion (BWIM) systems are based on a simple observation: when a heavy goods vehicle crosses a bridge, the bridge deforms by a small but measurable amount. By measuring this deformation iBWIM can measure the vehicles speed, weight and how its load is distributed over the vehicle's axles.

iBWIM systems can be used to gather both engineering and business intelligence.

By measuring the loading of the bridge, iBWIM data can be used to predict the residual lifetime of the bridge.

By identifying daily and weekly patterns in traffic, maintenance can be scheduled for minimum disruption.

By measuring goods traffic across the bridge we can assess the bridge's economic value.

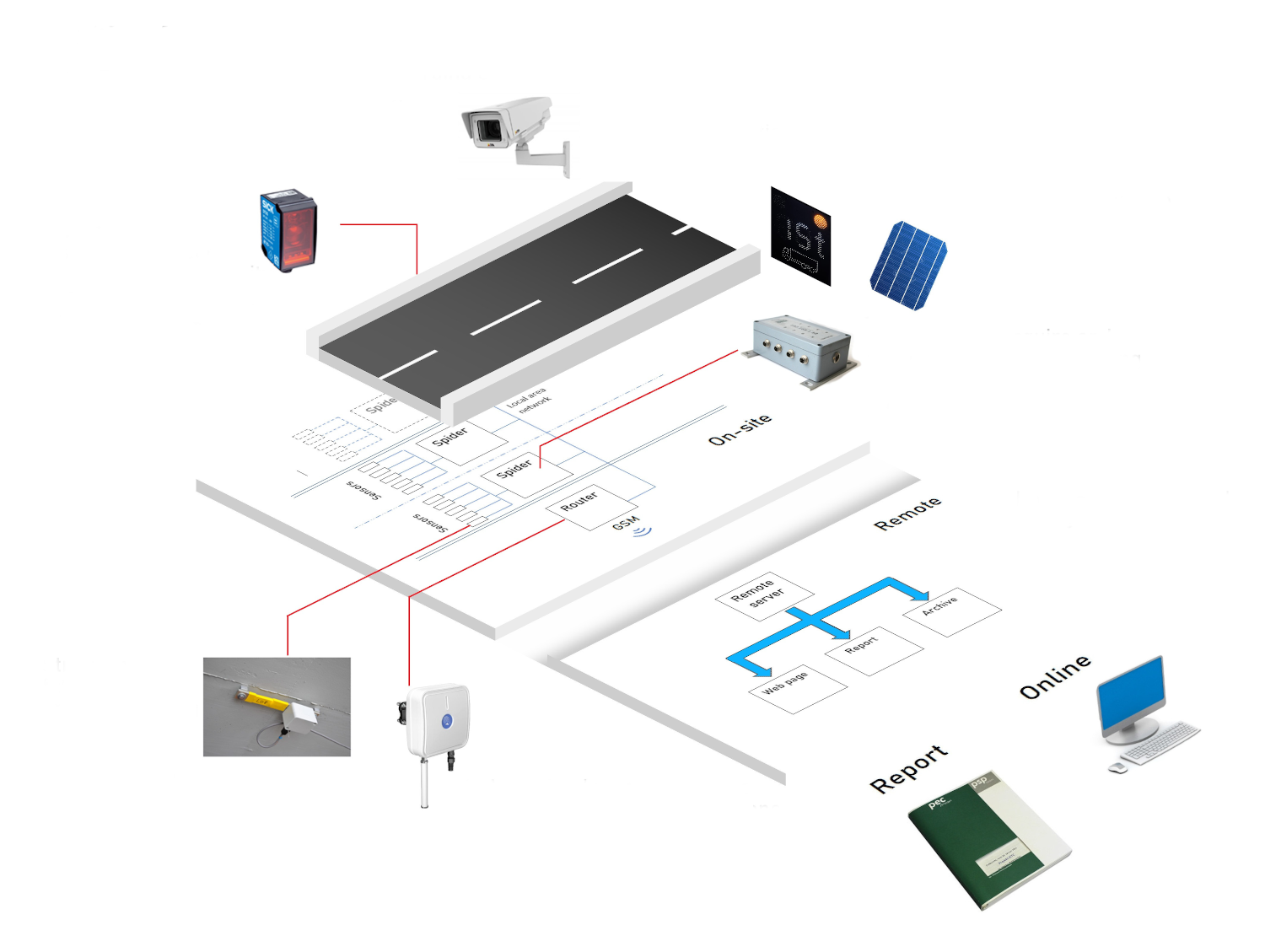

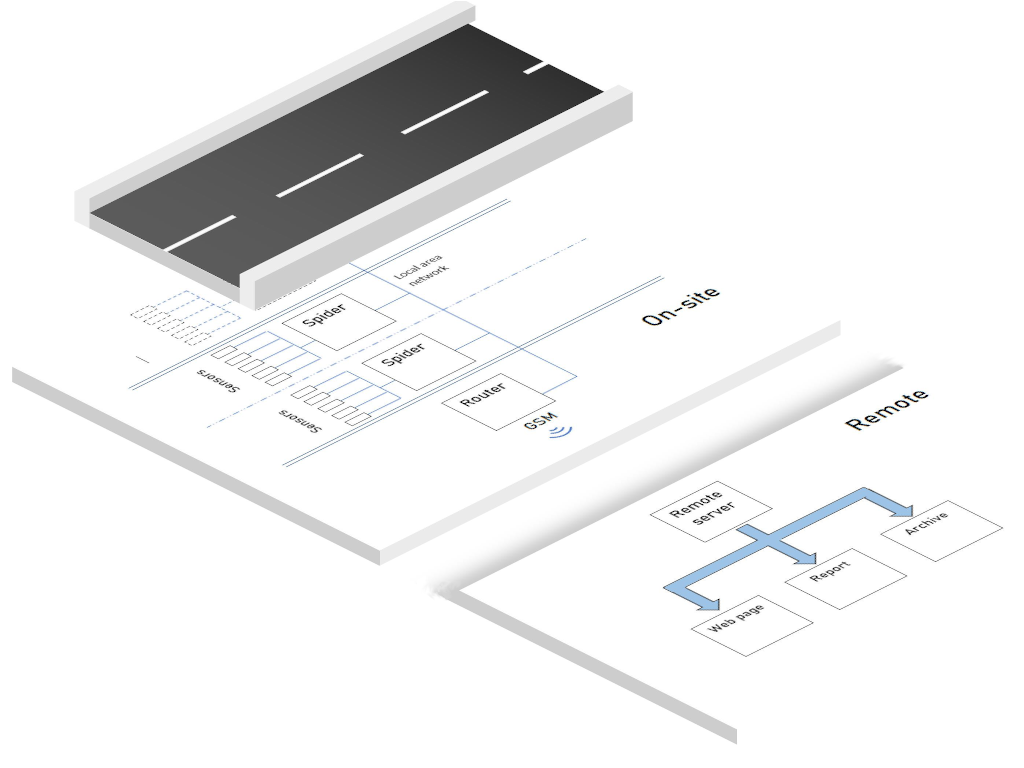

iBWIM has a lightweight embedded system on-site that transmits measurements to a remote server. The on-site system can be self-powered and only needs mobile network coverage.

Data is reported back to a central server for analysis, archiving and presentation. Reports can be compiled periodically and data can be presented in near real-time on our online user interface.

Unlike conventional Weigh in Motion systems, iBWIM is installed on the underside of the bridge—there is no need for traffic works and no disruption to traffic. This means that iBWIM can be deployed on even the busiest and most critical bridges, with no risk and no adverse economic impact.

Not all bridges are the same: in some we get high quality, well resolved signals; in others axle peaks merge and the signal is affected by harmonics. With high quality signal processing we can extend the range of bridges to which BWIM can be applied.

iBWIM uses fast, high bit resolution sampling of bridge deformation. Together with complementary measurements such as laser axle detection, iBWIM can resolve the contribution of individual axles, even on long bridges.

With a wide choice of sensors, output, power, communications and software options—iBWIM can be tailored to perform the tasks you need on your bridge.

For instance, with our solar and GSM modules, iBWIM can be deployed to remote sites that have little infrastructure support. Visual displays give drivers feedback about vehicle loading, and can direct vehicles of interest to laybys for inspection. CCTV with automatic license plate recognition allow overloaded vehicles to be tracked and open new possibilities for tolling heavy goods traffic.